From steel to sugar: Sucro revitalizes former Bethlehem Steel buildings in Lackawanna

Sucro Sourcing took on a daunting “before and after” challenge at the former Bethlehem Steel site in Lackawanna.

The “before” consisted of three run-down industrial buildings, remnants of the city’s steelmaking past.

The “after” is the sugar refinery and related operations Sucro created inside those buildings, bringing them back to life after decades of dormancy.

Rather than tear everything down and start anew, the sugar company chose to repurpose the facilities. The result is a blend of history and modern manufacturing within the brick walls.

“It’s been great for the company overall,” said Don Hill, Sucro’s chairman. “We had a chance to obviously revitalize the community. The buildings weren’t very much to look at before, but are now productive.”

Florida-based Sucro has poured $35 million into renovating the three buildings, plus adding a domed storage facility it built. The company already had a presence at the former Bethlehem site, handling packaging and distribution and liquid sugar processing. But the new project scaled things up and took fuller advantage of what the the location had to offer.

The company started up the new operations late last year and employs about 50 people. That headcount could be doubled a year from now, Hill said.

The heart of the new operations is the sugar refinery, inside the towering former Boiler House No. 3. The refinery illustrates both the challenges and the benefits that came with the overhaul.

The refinery, which revitalized the former Boiler House No. 3, is the heart of the new Sucro operations. Joshua Bessex/Buffalo News

In its thriving Bethlehem Steel days, the building supplied steam for plant process equipment and instrumentation. To make way for Sucro, construction crews extracted five gigantic boilers and patched up sections of the walls.

Sucro is using infrastructure that Bethlehem left behind. A massive hopper in the middle of the facility, once used for storing coal, was repurposed to store sugar. The company uses some of the old pipes to move steam through the refinery.

“You’ve got these pipes that are literally about an inch thick,” Hill said. “You’d never build them like that today. They’re incredible.”

Sucro is using some of the old pipes from Bethlehem Steel to move steam through the refinery. Joshua Bessex/Buffalo News

And it turns out that a building that stands over 100 feet tall is ideal for this type of manufacturing.

“From the outside, you would look at this and say, ‘This is the perfect physical configuration for a refinery,’ ” Hill said. “Refineries don’t take a lot of space, but they need height, because you utilize gravity.”

Sucro chairman Don Hill, inside a domed storage facility storing unprocessed sugar at Sucro. Joshua Bessex/Buffalo News

Farther down the property, Sucro revitalized the former Blowing Engine House No. 3 building. Inside, the company added a new concrete floor and 20-foot high concrete walls, to create a sturdy storage facility for sugar.

Sucro’s new investment is part of its expansion in the Buffalo Niagara region and in Southern Ontario.

In 2019, Sucro opened a refinery in Hamilton, Ont. The new operation in Lackawanna is designed to far surpass Hamilton’s facility in capacity. “This will be our flagship for a while,” Hill said.

Sucro recently announced it will build what it billed as Canada’s largest refinery, in Southern Ontario. The company has not specified the location but expects to open it in 2025.

“As we grow the business, we obviously learn. We get better with every step,” Hill said. “So we’re able to take it to a different scale with each new investment.”

Sucro has received strong support for its Lackawanna project, Hill said.

Sugar begins the refining process inside a large tank. Joshua Bessex/Buffalo News

The Erie County Development Agency approved $3.1 million in incentives, and the New York Power Authority allocated 5,000 kilowatts of low-cost power. And Sucro is eligible for nearly $700,000 in Excelsior Jobs Program tax credits through Empire State Development, if the company meets its job commitments.

Meanwhile, Sucro is awaiting an answer from the U.S. Department of

Agriculture on its application for a license under the Refiners Sugar Re- Export Program. Hill said the license allows domestic producers to be more competitive on a worldwide basis in acquiring sugar.

“We’re building desperately needed processing capabilities and adding competition to the industry,” he said.

The USDA said information about applicants for the program is confidential. But the agency said all applicants go through a rigorous review process, to ensure applicants meet the requirements, before a determination is made. “There is no set timeframe for the process,” the agency said.

The cost of the Lackawanna project nearly doubled Sucro’s earlier estimate of $19 million. Hill compared the process to renovating an old home, and finding more changes that need to be made, rather than building something brand new, when the work and costs are more predictable.

Even so, Hill said renovating the buildings kept the cost of the project far below what a brand-new refinery would have entailed.

Lackawanna mayor Annette Iafallo called Sucro’s investments “a significant step forward in our efforts to rebuild Lackawanna’s economy and increase local job opportunities.”

“Most companies would budget potentially half a billion dollars to build a new sugar refinery,” he said.

There’s also an environmental benefit to Sucro’s approach. “By repurposing these buildings, we prevent a lot of brick, steel and concrete from going to landfill, which is great for everyone,” Hill said. “Who doesn’t want to see something like that?”

Bethlehem Steel left behind lots of things, such as file cabinets filled with blueprints, after the company halted basic steelmaking in 1983.

Sucro preserved as many of those materials as possible. “You’ve got to make it practical, it’s a business, but you do want to keep a sense of history,” Hill said.

Sucro is also taking advantage of the site’s logistical advantages. Ships deliver raw sugar in a channel right alongside the property. And while Sucro transports its products by truck to food companies, the company will ship to faraway customers by rail, using railroad tracks on the property.

Sucro is making inroads in the growing organic sugar market, and has launched its own retail brand, called SweetLife.

While Sucro’s refinery has begun production, the company is still finalizing work on parts of the facility and stepping up production. It will take about three years for the refinery to reach full output, Hill said.

“Part of that is a function of us getting the refinery operating at those levels, but also building the sales,” he said. “You can’t sell it if you don’t make it, and really you can’t make it if you don’t sell it. It’s kind of a back-and-forth process.”

The renewed activity is a welcome sight for Donald Williams. He spent nearly 35 years working for Bethlehem Steel, including in buildings near the facilities Sucro has revitalized.

Williams recalls the days when the local Bethlehem operations teemed with 20,000 employees, an economic engine of the region. Bethlehem ended

basic steelmaking at the Lackawanna site in 1983, although some of its other operations carried on longer.

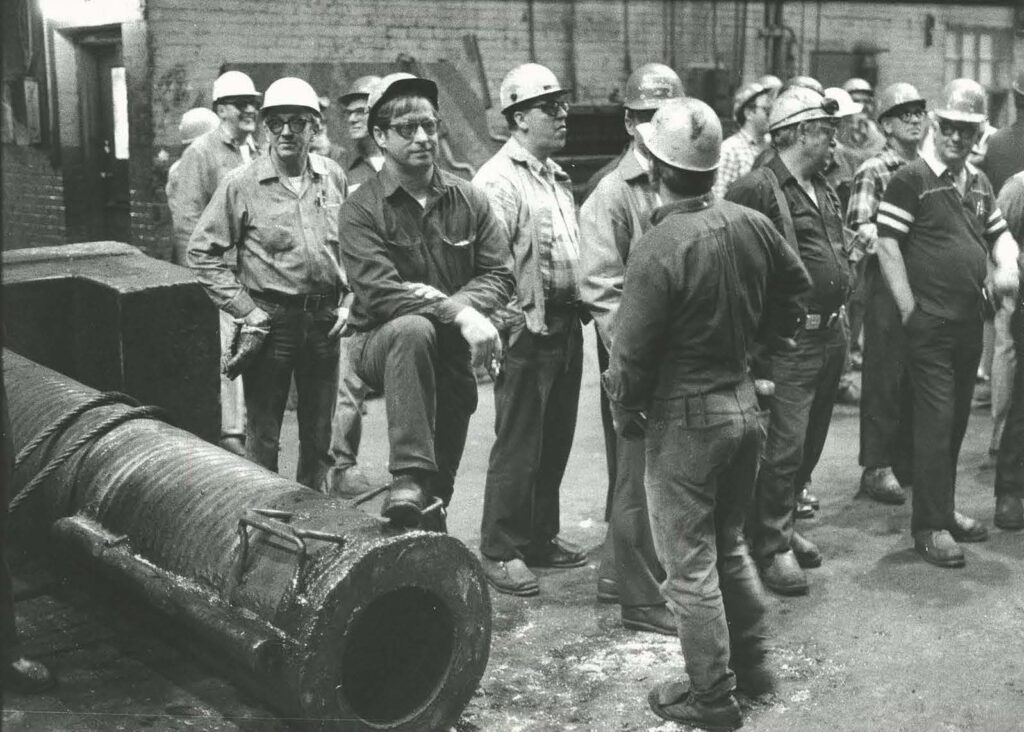

Bethlehem Steel workers put in a final day in October 1983 after the company ended basic steelmaking operations. Buffalo News file photo.

“We are so happy and pleased to see the progress that’s being made on that site, even though it’s taken years for things to really get organized there,” said Williams, president of the Steel Plant Museum of Western New York.

Lackawanna Mayor Annette Iafallo called Sucro’s investment “a tremendous boost for our city.”

“From an eyesore of long-abandoned structures which has haunted Lackawanna for over four decades since Bethlehem Steel closed will now stand a modern operation capable of serving Sucro Sourcing’s growing world-wide customer base,” she said.

Sucro’s operations are part of a broader revival on parts of the former Bethlehem property, where some new buildings have sprouted.

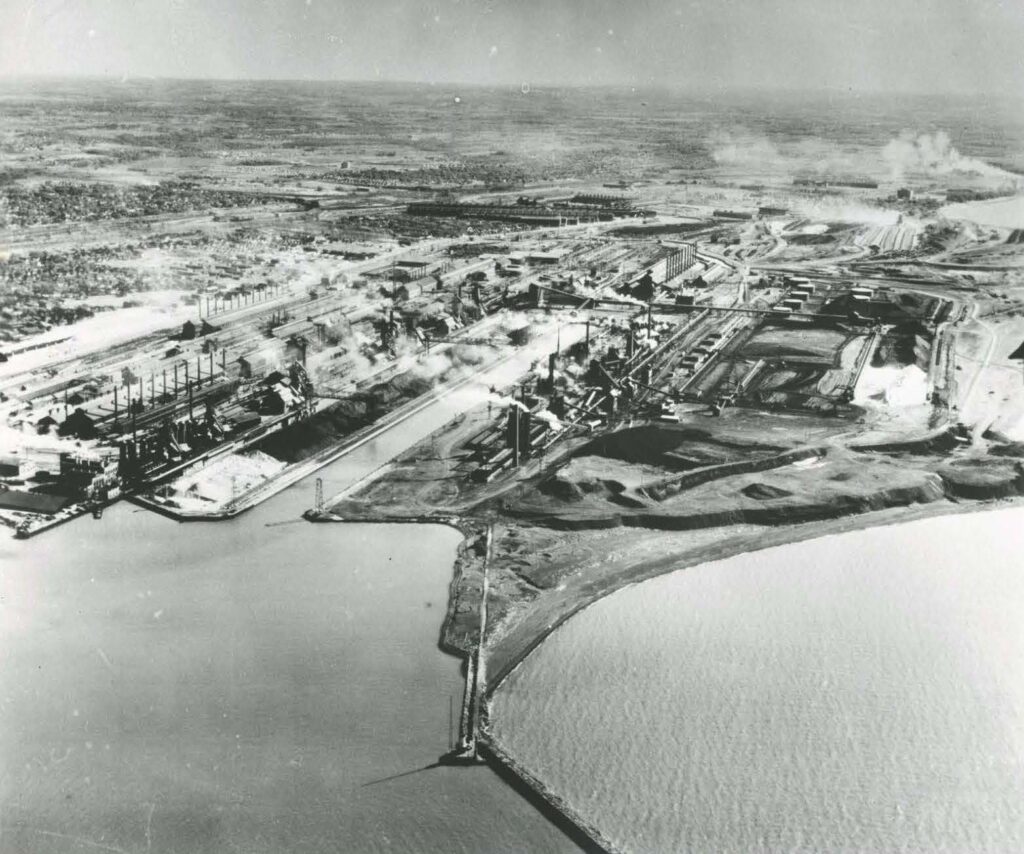

An undated photo of Bethlehem Steel. Buffalo News file photo

South of Sucro’s buildings, in Renaissance Commerce Park, TMP Technologies produces Mr. Clean Magic Eraser in a newly built facility. Elsewhere in that business park, Uniland Development has secured two tenants to fill a new warehouse, and is building a second, identical warehouse. Ciminelli Real Estate Corp. is planning its own warehouse in the park.

As Sucro moves forward with its plans, Williams and his fellow steel industry retirees at the museum marvel at what is unfolding at some long-neglected properties.

“To see activity over here, and the restart and the repurpose of some of the facilities that are still left over there is very gratifying, not only to us, but to the county and the taxpayers and everybody else,” Williams said.